What is a Borescope?

A borescope (occasionally called a boroscope, though this spelling is nonstandard) is an optical device consisting of a rigid or flexible tube with an eyepiece or display on one end, an objective lens or camera on the other linked together by an optical or electrical system in between. The optical system in some instances is surrounded by optical fibers used for illumination of the remote object. An internal image of the illuminated object is formed by the objective lens and magnified by the eyepiece which presents it to the viewer’s eye.

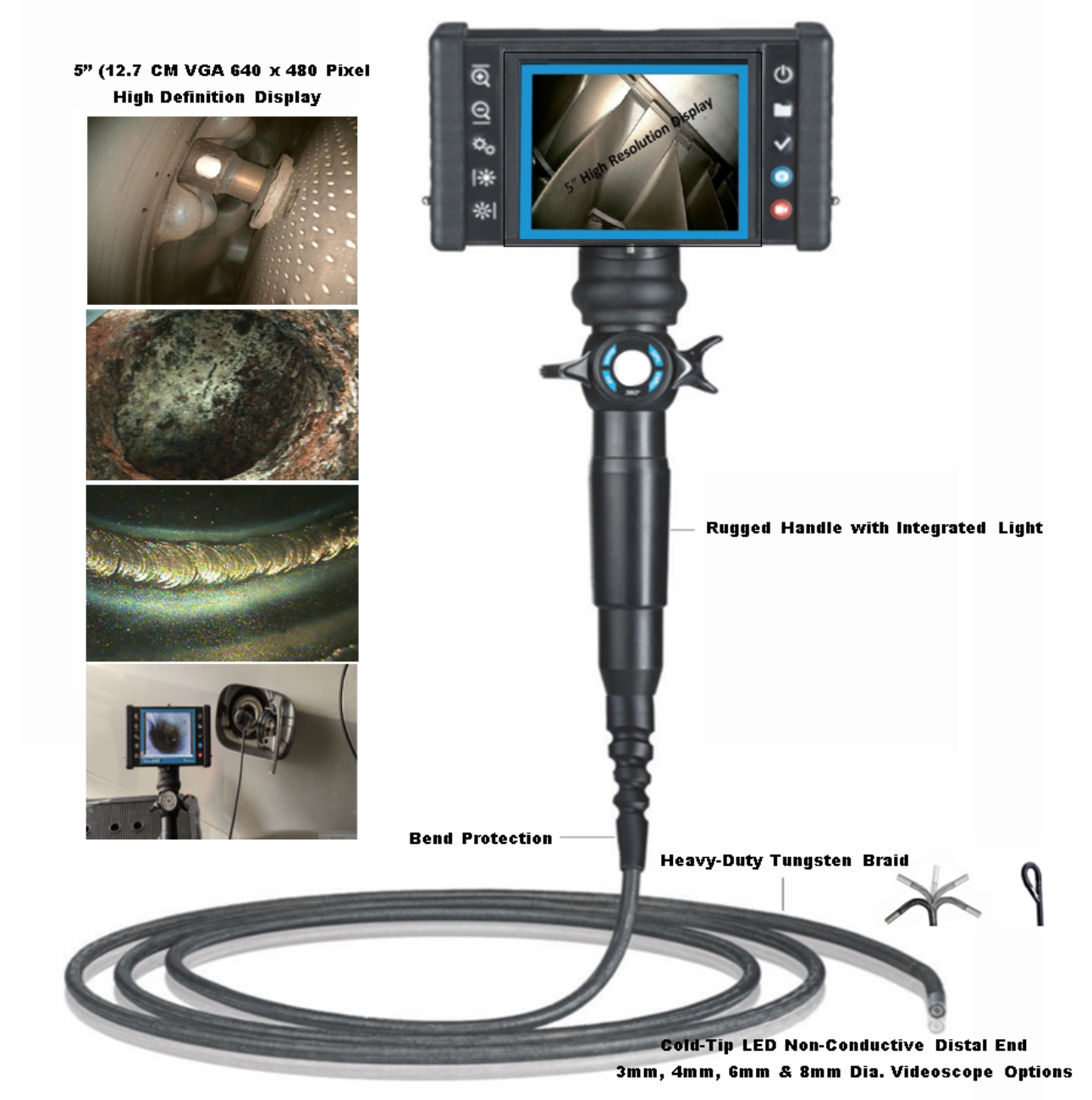

The best borescopes are rugged, offer clear, bright displays, and have a variety of uses.

Today’s borescopes – videoscopes / inspection cameras have a monitor, a cable and a small camera mounted at the end of the cable. You can run the cable down a small cavity or a pipe to begin your visual inspection.

1. Aircraft Engine Turbine Inspection.

2. Gas Turbines Engine inspection. Common engines such as Solar

Turbines.

3. Wind Power Turbine Inspection.

4. Explosion Proof & Volatile Environments, such as Gas Pipelines,

Border Patrol inspection vehicle gas tanks.

5. Welding Inspection, using borescopes to inspect weld joints in an enclosure.

Much like any other tool, borescope costs run the gamut. For industrial applications, you need a serious borescope that not only provides clear, bright images in tight spaces, but also offers features such as articulation, dual view, video capture, image compare. Other factors to consider are the size of the probe and the working length of the cable. All these requirements factor in to the cost of a borescope.

When budgeting for a high-end borescope purchase, make sure to take into account the ruggedness of the scope and potential repair costs/warranties. Is your work environment such that you’re constantly needing to repair inspection equipment? Some companies charge almost as much to repair a borescope as to buy a new one.

Does this sound like we’re dodging the question? Our point is that a good quality borescope from a company that stands behind their products will cost from $5500 to $15,000 – the exact cost will depend on your exact needs. If you’re hoping to get that same quality from a $40 Amazon borescope, expect to be disappointed.

WiFi-enabled borescopes allow you to stream photos and videos coming in from the borescope right to your iPhone or Android! Borescopes for iPhones and borescopes for Androids are cool because everyone around you can see the live feed of an inspection being in real time.

A video borescope or “inspection camera” is a flexible borescope that uses a miniature video camera at the end of the flexible tube. The end of the insertion tube includes a light which makes it possible to capture video or still images deep within equipment, engines and other dark spaces.

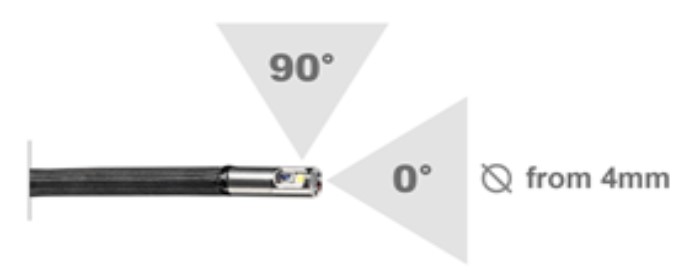

Some of our video borescope or “inspection cameras” have (2) cameras, one to see the front view and the other to see the side view, all at the same time! This means that you don’t have to constantly look around the area, you can have almost a 180 degree field of view in one swoop!

Dual-view borescopes have 2 cameras, one to see the front view and one to see the side view, at the same time. This saves you from having to reposition the scope, and lets you compare two live images to each other at the same time.

An inspection camera, or borescope, is an instrument that functions like a camera, microscope, or telescope: it enables you to observe areas that are too cramped, too far away, or entirely out of reach. Some of the cameras provided can have up to 5 Meters of cable length!

It is called a camera because there is a very small High Resolution camera at the end of the Scope tip which you can use to take photos or video, and then store the captures in a SD card provided with the Videoscope – Inspection Camera!

If you are need to inspect oil pipelines or gas tanks, make sure your inspection camera is hazardous-environment rated. Most inspection cameras/borescopes are not safe for use in combustible environments!

1. First take a look at the diameter of a hole, or a cavity that you need to insert the borescope. This is called Borescope diameter.

2. Then take a look at how far is the target that you wish to inspect? Is the target a meter away, or 2 meters? This is called the Working Length of the Scope.

3. This video shows a bit about how an Explosion Proof Borescope – Videoscope / Inspection camera is used to inspect inspect an inside a vehicle’s gas tank. This type of Explosion Proof Borescope, is often used by Border Patrol officers.

Aviation engine borescopes are one type of industrial Videoscope – commonly known as Video Inspection Cameras. Simply speaking, they are instruments that detect and view the internal parts of an aircraft, such as:

1. Aircraft Turbine Engine; check for overheated, cracked damaged

blades as well as inspecting of Foreign Object Debris commonly

known as FOD.

2. Aircraft Engine Air-Intakes.

3. Cracked fuel lines.

4. Check the ignitor ports.

5. Combustion chambers.

Mercedes Benz and other automotive industry leaders use our brand of borescope to inspect installed components and parts, such as valves, pistons or cylinder tracks, without disassembly.

An aluminum engine can only function reliably if the cast components are free of sand and release agents. So-called blowholes can occur during production. With video borescopes from I.T.S. Videoscopes, you can see into channels with the smallest diameters. Indirect visual inspection provides clarity in troubleshooting. UV-based systems are also available for more specific applications, making cracks, faulty corrosion protection or poorly welded doublings visible.

The combustion chamber of combustion engines of any kind is extremely important during development as well as in the repair shop. Visual inspection with an I.T.S. Videoscope increases quality and reduces the complaint rate in your production.

I.T.S Videoscopes – IT Concepts offers one of their Automobile

approved Videoscopes for vehicle engine inspection.